Product Classification:Parpetal needle roller and cage assembly

Product Description:

Note: Please press "Ctrl+F" on the keyboard to enter the model you want to query.

- Product Details

- Product Description

-

- Commodity name: Parpetal needle roller and cage assembly

- Commodity ID: 010

The centripetal needle roller and cage assembly is a complete bearing unit composed of cage and needle roller. It is mainly used for shafts and bearing housings that can be used as raceways, and has the ability to withstand high loads and high rigidity with the minimum radial structural space. Under the high-precision shaft and seat hole raceway, higher rotation accuracy can be obtained; The working clearance can be adjusted according to the needle roller, mounting shaft and seat hole. The installation is very convenient, and it is a very economical bearing used under harsh conditions.

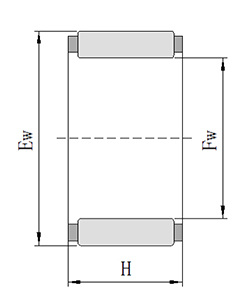

centripetal needle roller and cage assembly model number dimensions base load rating N limit speed rpm Fw Ew H CR quiet Cor lubricated with oil K15×19×13 15 19 13 8500 10900 24000 K15×21×21 15 21 21 19400 24300 24000 K16×20×10 16 20 10 7800 9900 24000 K16×20×13 16 20 13 8900 11800 24000 K17×21×13 17 21 13 10400 14600 23000 K18×22×13 18 22 13 9200 12700 22000 K18×24×20 18 24 20 20200 27000 22000 K19×23×13 19 23 13 9500 13500 22000 K19×23×17 19 23 17 12500 19200 22000 K20×24×17 20 24 17 12900 20400 21000 K20×24×23 20 24 23 18300 26000 21000 K20×26×17 20 26 17 19200 26000 21000 K20×30×19 20 30 19 23900 28500 21000 K20×36×24 20 36 24 35500 41500 18000 K22×27×13 22 27 13 13700 22700 20000 K22×28×20 22 28 20 19400 27000 20000 K24×28×22 24 28 22 14500 25000 19000 K24×30×17 24 30 17 19500 27500 18000 K25×30×20 25 30 20 21700 36500 18000 K25×30×24 25 30 24 24000 39000 18000 K25×30×26 25 30 26 28000 42000 18000 K25×32×25 25 32 25 32000 43000 17000 K25×33×24 25 33 24 34000 47000 17000 K25×35×24 25 35 24 42000 55000 17000 K26×30×17 26 30 17 15200 27500 18000 K28×33×27 28 33 27 23300 40500 16000 K28×35×25 28 35 25 33000 49000 16000 K29×35×23 29 35 23 32000 42000 15000 K30×35×20 30 35 20 25500 49000 15000 K30×35×24 30 35 24 28000 53000 15000 K30×35×25 30 35 25 28500 55000 15000 K30×35×26 30 35 26 29000 57000 15000 K30×35×27 30 35 27 30500 59000 15000 K30×38×16 30 38 16 26000 38500 15000 K30×38×25 30 38 25 32000 40000 15000 K30×46×28 30 46 28 49000 69000 13000 K32×37×25 32 37 25 25500 45500 14000 K32×37×27 32 37 27 30000 60000 14000 K32×37×30 32 37 30 33800 65500 14000 K32×42×25 32 42 25 37500 58000 14000 K32×46×32 32 46 32 66000 84000 14000 K35×40×23 35 40 23 29000 58000 13000 K35×40×27 35 40 27 32000 62000 13000 K35×41×25 35 41 25 31000 60000 13000 K35×42×25 35 42 25 30000 49000 13000 K35×45×20 35 45 25 45000 68000 12000 K35×47×20 35 47 20 53000 79000 12000 K37×42×20 37 42 20 22400 43000 12000 K37×42×31 37 42 31 30500 58000 12000 K38×44×25 38 44 25 30000 58000 12000 K38×44×27 38 44 27 31500 68000 12000 K38×46×20 38 46 20 35500 57000 12000 K38×47×32 38 47 32 40000 62000 12000 K40×45×27 40 45 27 33000 73000 12000 K40×48×20 40 48 20 36000 59000 11000 K42×47×17 42 47 17 21700 43000 11000 K42×48×35 42 48 35 41500 65000 11000 K42×50×20 42 50 20 35000 57000 11000 K43×48×27 43 48 27 33500 75000 11000 K43×49×31 43 49 31 42500 82000 11000 K45×50×17 45 50 17 22500 46000 10000 K45×59×36 45 59 36 73000 103000 9500 K46×52×37 46 52 37 35000 83000 10000 K48×54×25 48 54 25 35000 83000 9500 K48×54×29 48 54 29 37000 41500 9500 K50×56×30 50 56 30 39000 97000 9500 K50×56×35 50 56 35 44000 81000 9500 K51×61×32 51 61 32 40000 99000 9500 K51×61×38 51 61 38 41000 102000 9500 K52×56×32 52 56 32 10400 15900 9500 K52×59×35 52 59 35 32000 65700 9000 K55×60×30 55 60 30 41000 108000 9000 K55×61×20 55 61 20 32500 70000 8500 Note: 1. The basic load rating and limit speed data listed in the table are for reference only. 2. The limit speed during grease lubrication is 60% of the oil lubrication value listed in this table. Key words:- machinery

- bearings

-

The centripetal needle roller and cage assembly is a complete bearing unit composed of cage and needle roller. It is mainly used for shafts and bearing housings that can be used as raceways, and has the ability to withstand high loads and high rigidity with the minimum radial structural space. Under the high-precision shaft and seat hole raceway, higher rotation accuracy can be obtained; The working clearance can be adjusted according to the needle roller, mounting shaft and seat hole. The installation is very convenient, and it is a very economical bearing used under harsh conditions.

This series of bearings are mainly used for transmission shafts and gear boxes of automobiles, motorcycles and construction machinery.

1. Type and structure

This product of our company can be divided into three types according to the materials used for the cage: car made, stamping and reinforced nylon. According to the structural form of the cage, it can also be divided into M type, K type and other structural forms (see figure). The materials and structural forms can be designed according to the user's requirements.

2. Product precision

The difference between needle diameters is 2 μ m. The accuracy class is G2 (international GB/T309).

The upper deviation of the nominal width Bc of the component is -0.20, and the lower deviation is -0.55.

Technical requirements can also be determined separately according to user requirements.

3. Materials

The needle roller is made of GCr15 bearing steel.

Cage materials can be high-quality low-carbon steel, low-alloy steel and reinforced nylon according to different application occasions and requirements.

Copyright © Chengdu West Jingcheng Bearing Manufacturing Co., Ltd. Powered by www.300.cn SEO