Product Classification:Needle bearing for stamping outer ring (full needle series)

Product Description:

Note: Please press "Ctrl+F" on the keyboard to enter the model you want to query.

- Product Details

- Product Description

-

- Commodity name: Needle bearing for stamping outer ring (full needle series)

- Commodity ID: 009

Punched outer ring needle roller bearing (full loaded needle roller series) is a bearing unit composed of thin-walled outer ring and needle roller. Its main characteristics are that the grinding shaft is used as the raceway, the radial space structure is particularly small, the cost is low, the bearing capacity is high, and the installation is convenient. This series of bearings are widely used for supporting running components such as automobiles and motorcycles.

Stamped outer ring needle roller bearings (full needle series). model Dimensions mm base load rating N limit speed rpm new model older models Fw D H Cr quiet Cor lubricated with oil F/6×10×7 941/6 6 10 7 2400 1420 7500 F/7×12×8 941/7 7 12 8 3100 17500 7500 F0810 - 8 12 8 4050 7150 7400 F0813 - 8 13 9 4100 7300 7400 F/8×14×10 941/8 8 14 10 5200 7150 7300 F/8×14×12 942/8 8 14 12 4550 7150 7300 F0914 - 9 14 9 4600 7200 7200 F/9×15×10 941/9 9 15 10 8000 11500 7100 F/9×15×13 942/9 9 15 13 8560 12800 7100 F/10×16×10 941/10 10 16 10 6350 10800 7200 F/10×16×15 942/10 10 16 15 6890 11500 7100 F1019 - 10 19 11 9000 10000 6100 F/12×17×12 941/12 12 17 12 8400 11900 7100 F/12×17×15 942/12 12 17 15 9000 12500 7100 F/12×17×18 943/12 12 17 18 9800 13500 7100 F1410 - 14 20 10 8100 10000 7100 F/15×20×12 941/15 15 20 12 8400 11900 7100 F/15×20×16 942/15 15 20 16 9500 12800 7100 F/15×20×20 943/15 15 20 20 10500 16000 7100 F/17×23×14 941/17 17 23 14 12500 22500 7300 F/17×23×18 942/17 17 23 18 13800 24800 7300 F/17×23×22 943/17 17 23 22 21700 21400 6100 F/20×26×14 941/20 20 26 14 15800 40500 6900 F/20×26×20 942/20 20 26 20 18800 42500 6900 F/20×26×25 943/20 20 26 25 20500 35500 6300 FY/22×29×25 948/22 22 29 25 23500 47800 5100 F/25×32×16 941/25 25 32 16 18700 37900 5100 F/25×32×22 942/25 25 32 22 11000 16500 5100 F/25×32×25 943/25 25 32 25 11500 18500 5100 F/30×38×16 941/30 30 38 16 25500 57500 4600 F/30×38×24 942/30 30 38 24 28800 64500 4300 F/30×38×32 943/30 30 38 32 34500 78900 4300 F/32×40×32 943/32 32 40 32 35500 66200 4300 F/35×43×16 941/35 35 43 16 23500 68000 3700 F/35×43×25 942/35 35 43 25 38700 86200 3200 F/35×43×32 943/35 35 43 32 40500 97800 3200 F/40×50×32 942/40 40 50 32 42500 108000 2600 F/40×50×38 943/40 40 50 38 44800 118500 2600 F/45×55×38 943/45 45 55 38 45800 128000 2900 Note: 1. The basic load rating and limit speed data listed in the table are for reference only. 2. The limit speed during grease lubrication is 60% of the oil lubrication value listed in this table. Key words:- machinery

- bearings

-

Punched outer ring needle roller bearing (full loaded needle roller series) is a bearing unit composed of thin-walled outer ring and needle roller. Its main characteristics are that the grinding shaft is used as the raceway, the radial space structure is particularly small, the cost is low, the bearing capacity is high, and the installation is convenient. This series of bearings are widely used for supporting running components such as automobiles and motorcycles.

1. Structural form

This type of bearing is of perforated type and sealed type, and the applicable shaft diameter is generally φ 6~ φ 45mm range.

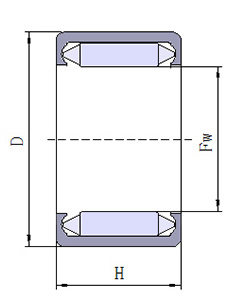

2. Product precision

The difference between needle diameters is 3 μ m. The accuracy grade is G3 (international GB/T309), which can also be determined according to user requirements.

The tolerance of outer ring width C is 0 to -0.3mm

Due to the deformation of thin-walled outer ring after heat treatment, the dimensional accuracy of outer ring D and inscribed circle diameter cannot be inspected under the free state before installation, and shall be inspected as follows:

1) The diameter tolerance of the inscribed circle Fws is checked by pressing the bearing into a hardened steel ring gauge with a specific inner diameter and then using a plug gauge with a "go" and a "no go" end.

2) The test of outer ring D tolerance is best determined by testing the bearing's pressing force when pressing the ring gauge in 1) above.

3. Materials

The needle roller is made of GCr15 bearing steel.

The stamping thin-walled outer ring is made of high-quality low-carbon steel.

4. Precautions for use and installation:

The thin-walled outer ring shall be equipped with a rigid seat hole to give full play to its bearing capacity.

The bearing shall be pressed into the bearing seat hole with an assembly mandrel. The shoulder of the assembly mandrel shall contact the bearing marking surface, and the non marking surface cannot bear the assembly force directly.

Copyright © Chengdu West Jingcheng Bearing Manufacturing Co., Ltd. Powered by www.300.cn SEO